Nauta Design and the Nilaya: “We designed our 48-metre in light and fast aluminium” – Interview by DN

Interview with Mario Pedol and Massimo Gino, founders and managers of Nauta Design, who share with us how their design studio started and the behind the scenes story of the design of Nilaya, one of their latest achievements

Interview with Mario Pedol and Massimo Gino, founders and managers of Nauta Design, who share with us how their design studio started and the behind the scenes story of the design of Nilaya, one of their latest achievements

Massimo Gino and Mario Pedol founded Nauta Design in 1985. They have achieved an international reputation for their design of custom and series sail boats from 30 to 130 feet, but they have also worked on motor yachts of all sizes, up to the 180 metre Azzam, currently the largest private yacht in the world.

We interviewed them to find out how they started their design studio, to find out more about their design process, and to learn more about Nilaya, one of their recent designs focused on lightness and performance.

Mario Pedol and Massimo Gino, how did you start working together, and how did Nauta Design begin?

“Nauta – explains Pedol – started from a passion for sailing and the sea. In the 1970s, with a friend and just for fun, we took on a commission (through architect Andrea Vallicelli) for a Mini Tonner called ‘Avventura 703’ (7.03m) which was a surprising success (40 units built and sold). This led me to leave university and dedicate myself full time to my real passion.

I founded a company called Nauta Imports, working as representative and dealer in Italy for Oyster Marine, but after a few years, the exchange rates and fees made it inconvenient to import boats from England, so I decided to change things and purchased a ‘demo boat’ to begin working in Caribbean charters with a friend, On our way back to Europe we nearly sank and had to stop over in Lisbon for a few weeks for repairs.

My friends who helped me during that time are still some of the most important people in my life. One became my wife, while the others, Massimo Gino and Enzo Moiso (who died in 2009), became my partners in Nauta. Even though I had experience in sailing and selling boats, at that time i didn’t know enough about how they were designed and built. So, after my return from the Caribbean, I enrolled in a yacht design course in Milan. I then took on an apprenticeship in New York with Scott Kaufman, former designer for Sparkman & Stephens, whose style strongly influenced me as a designer.

Once I returned to Milan, I convinced Massimo Gino and Enzo Moiso to join me in an even bigger project: we put together all the money we had and founded a new Nauta to design and build the first Nauta 54. At that time we were builders as well as designers. Nauta worked on the deck layout and interiors, while Scott Kaufman designed the hull, appendages and sail plan. We brought the boat to the Genoa Boat Show in 1986, and it did fairly well. Over the next few years, we built a total of seven Nauta 54s, four Nauta 70s and four Nauta 65s. Then, in the early 1990s the downturn in the market led us to abandoning the construction side of the business to concentrate on design, and that is what we are still doing today, nearly 40 years later.”

You started with sail boats, and then moved on to mega motor yachts. How did this transition take place?

“In truth, already in the early 1990s Nauta was called upon by Bertram Yachts to redesign the interior of their 43’, and then of the entire range, which was very successfully manufactured for a number of years. So it is a mistaken perception that Nauta only recently started working on motoryachts.

What is true is that we were recognised by critics and the market especially for our sailing designs up until around 15/20 years ago, so in Nauta’s first 20 years of business, and it is also true that our passion for yacht design stemmed from our passion for sailing, but not exclusively. The water, the relationship between humankind and the marine environment have always been at the heart of our interests, and, above all, Nauta has always wanted to explore diverse projects, working on designing vessels of different sizes, functions (while remaining in the pleasure boat sector) and performance, always trying to express our ideas and style in a number of different vessels.

From the 180-metre Azzam built by Lurssen to the Oceanis 30.1, you can always see a certain style, approach and even a ‘signature’ style that has developed over the years, focussing on timeless beauty, without excess, or useless and non-functional elements to the design. After working with Bertram and Toy Marine in the early 2000s, Nauta began taking on a more important role in motoryacht design with the exterior design of Azzam and our partnership with Cantiere delle Marche, leading us to designing and building five CDM Nauta Air in just a few years.”

You have an excellent reputation in shipyards around the world. How do you start creating a design when you are commissioned by a shipyard? How far does your “free rein” go?

“There are a number of different designs and boats and there is no general rule, the main distinction is between custom and series design, which are very different from each other, because, in one case the reference is a private client, in the other the boat needs to be appreciated by not just one person, but many – the client, and the market – so we need to create solutions that, while still original, are more conventional and economically sustainable for the builder.

When the client is a shipyard, the limits we have to work with as designers are defined each time depending on manufacturing cost estimates, required technical specifications, and standards to follow. In series designs there are more constraints tied to manufacturing costs, compared to custom work, but, in general, it is clear that we have ample space to be creative, while respecting time lines and costs.”

Obviously, in addition to builder’s construction needs, you need to also consider the owner. How do you work with them?

“Creating a yacht is not an easy process, but it is almost always interesting and stimulating, and we accompany the client in defining the functional and aesthetic characteristics that their boat will have. The yachts we design are there to create life experiences, to have unforgettable voyages. So the essence of our role as yacht designers is to use the design to enhance the on board experience for the owner and their guests.

Each yacht has its own personality, defined by the lifestyle and preferences of its owner. This is why it is fundamental to put ourselves in the client’s shoes, to listen and understand them, figure out their tastes and preferences, to fully immerse ourselves in their future experience. Series production and full custom vessels are two different worlds, for many aspects very far from each other, but the principle is the same, to interpret the owner’s desires, understand how they will use the boat, and design what they are dreaming of. All of Nauta’s designs have been developed in close and friendly partnership with their owners, and they are a fundamental part of every design, along with their personality and style.”

Is there a design you are particularly tied to? And why?

“In truth we are tied to all our designs, because each one has been a special experience and a lesson. Designing yachts with a timeless excellence, creating a signature style for our exteriors and interiors, integrating all the different parts into the design with a holistic vision, where the vessel is all one and the interior and exterior communicate seamlessly: this has always been the main goal of our work. Being able to do this on such a variety of project, from sailing to motor, series and custom, small and mega yachts, led us to become versatile in creating elegance, which is something we are known for by critics around the world and by the market. This success came thanks to all of our designs put together, so this ties us to all of them equally.”

You also designed “Azzam”, which is considered to be the biggest private yacht in the world. Certainly there are many stories behind that project. Can you share one with us?

“I remember that from the very beginning I was stunned with the gigantic size of the vessel. We had already worked on a number of different designs, but none of that size. During one of Lurssen’s presentations, they shared some interesting information regarding its construction. I remember that they shared that if Azzam were to be built by only one person, in order to complete it on time, that person would have had to start working on it in 1737 BC, considering the number of hours needed to complete it. This gives you an idea of the gigantic size of not only the finished piece, but also of the structure and the organisation that made such a feat possible in just a few years.”

One of your recent and successful designs was Nilaya, where you curated the interior and exterior. What are its strong points?

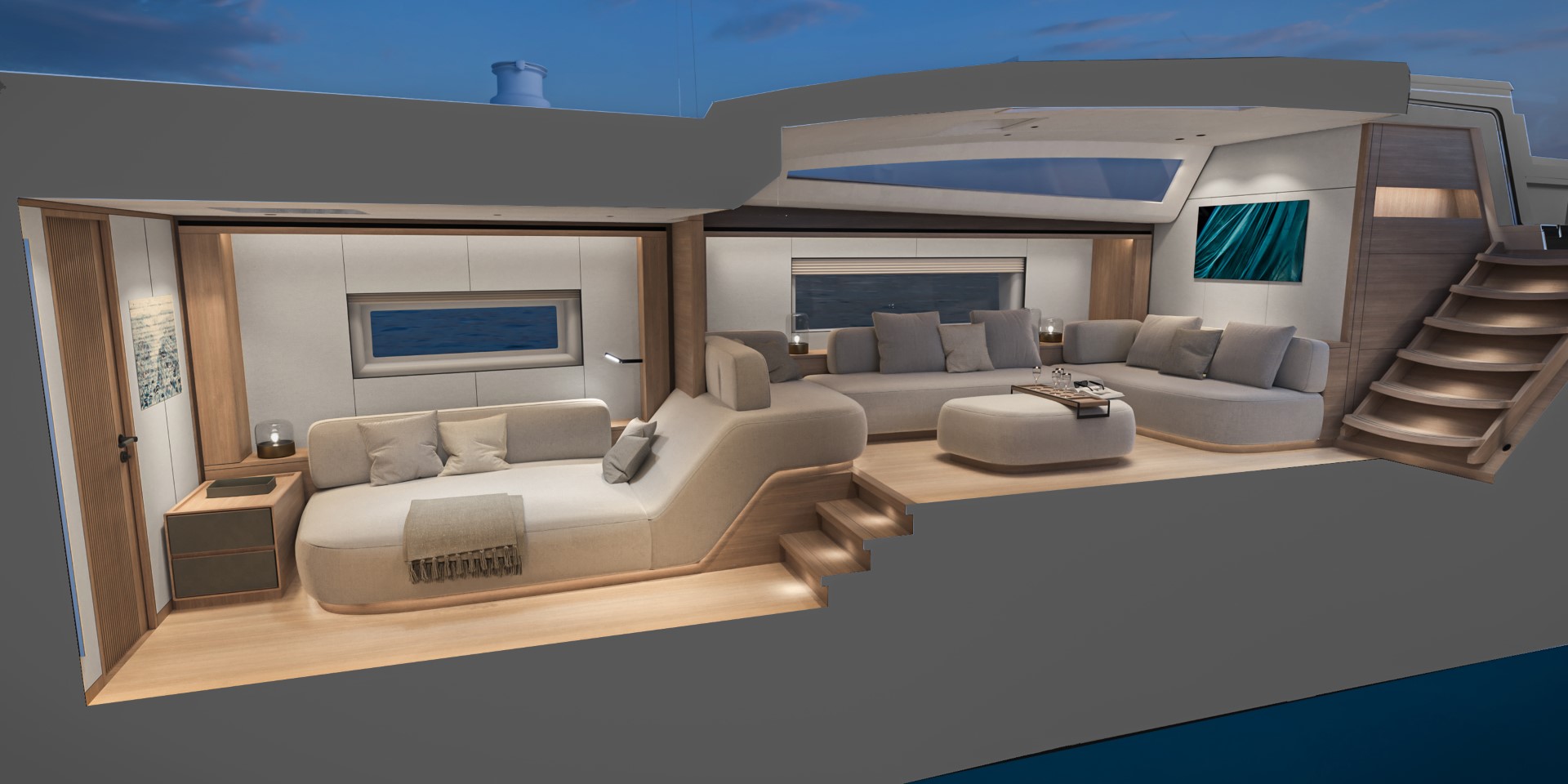

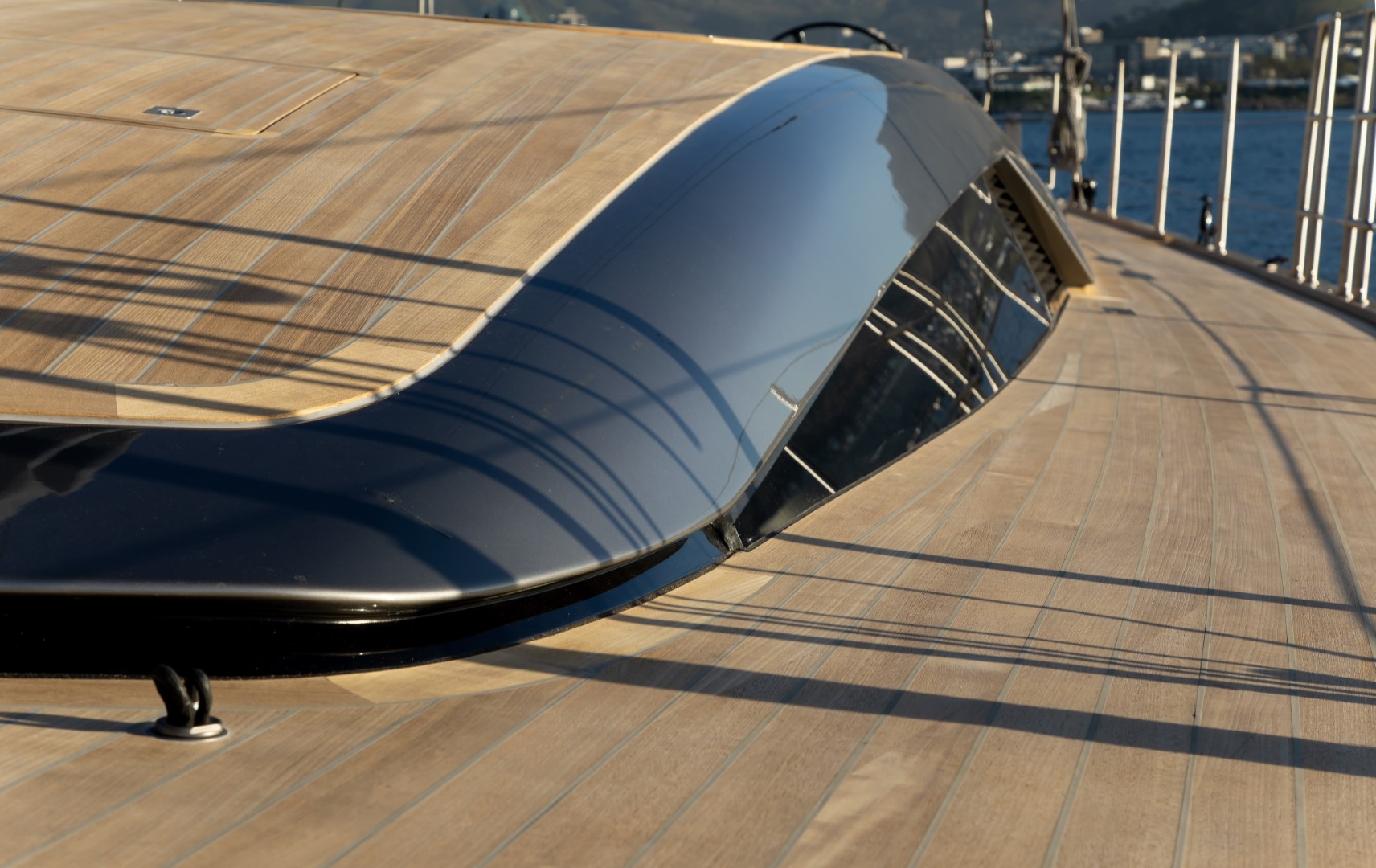

“Nilaya’s biggest qualities [designed by Reichel/Pugh (naval architecture) and Nauta (exterior and interior design)], is that it has a unique design for its size (around 48 metres length) and is extraordinarily light for its bulk, on the back of its construction by Royal Huisman, and before that, by Nauta’s preliminary research.

This is a story worthy of being told. Nilaya’s expert owner is a Nauta client, who wanted a superyacht combining the best of speed, safety, robustness and silence, and that was also efficient and modern with a powerful sail plan. This demanding brief ( because reconciling performance and comfort on a hull of this size is not easy) led us to think deeply about the advantages and disadvantages of a possible aluminium construction compared to carbon fibre.

Speed was clearly important to the owner and the first idea was to build in carbon fibre, because a hull made of this is lighter, and generally faster than one in aluminium. But in terms of size, Nilaya is on the cusp of where carbon fibre building becomes more expensive and requires more time to build. On the other hand, aluminium guarantees comfortable navigation and more resistance to collisions. From the beginning, Nauta decided to consider and scrutinise both options regarding construction material, so that the client could make an informed decision based on solid data.

The s/y Nilaya

When looking at the current existing fleet of aluminium yachts of similar size, we could see a difference in displacement of around 50%. This notwithstanding the fact that the hull, deck and superstructure represent, all together, only 15% of the total displacement of a boat. So we asked ourselves a simple question: could we design an aluminium yacht that was closer in displacement to a carbon fibre boat of similar size?

In order to test our idea, Nauta began preliminary research even before the design went to tender to find the shipyard and naval architect. Together with Roberto Bisconti, a naval architect who has worked in several America’s Cup campaigns with different teams, we produced two 3D models, one for a potential aluminium hull and one in carbon fibre but with the same speed/sail surface ratio, using a VPP (Velocity Prediction Program).

The results showed that, while the carbon fibre boat was slightly faster to the stern, when close-hauled, performance was more or less the same. This was sufficient to convince the owner to go for the aluminium option as the minimum loss in performance was compensated by the fact that a hull in this material is quieter, more resistant to impact and easier to repair, an important characteristic for a yacht built for travelling around the world.

At this point, Royal Huisman, world specialists in building aluminium super yachts, enthusiastically supported Nauta’s vision, and took on the challenging objective of building a superyacht with a considerably lighter displacement than the current fleet of aluminium vessels, and it was then logically chosen as ship builder. In order to make the yacht as light as possible, the Dutch shipyard engineered and built an aluminium frame (hull and forward and aft decks) with parts in composite (deckhouse, guest cockpit and lateral decks). Rondal, Royal Huisman’s sister company, built the “Panamax” mast and boom in carbon fibre, while, in order to guarantee optimal performance, the client chose Reichel/Pugh as naval architects.

Basing themselves on over a dozen CFD configurations conducted together with the specialists of America’s Cup, Cappinnetto, Hueber and Giorgio Provinciali for VPP analysis, Reichal/Pugh further perfected the hull for hydrodynamic optimisation, meaning speed and stability while sailing. Particular attention was also paid in keeping the retractable keel as long as possible, as a longer fin allows for the use of a lighter fin keel for the same straightening movement. Thanks to our preliminary research, to Royal Huisman’s light construction and the further optimisation done by Reichel/Pugh, Nilaya represents a new standard in aluminium construction, with a displacement of around 20% more than an equivalent full-carbon fibre boat of similar size, and much less than any other aluminium yacht currently existing. A design that offers high performance, combined with robustness and acoustic comfort, for extended bluewater sailing.”

What designs is Nauta currently working on?

“We are working on a number of interesting projects, all different from each other. The most significant in terms of size and volume are a 130+ metre over 9000GT, under construction in Northern Europe, for which Nauta did the interior design, and two 70 metres: the Thunderball under construction by CRN Yacht (Interior design) and the Moonflower, under construction by Winder (exterior and interior design). Then there are another three vessels under construction by Cantiere delle Marche, the Flexplorer 146-35 and two CDM-Nauta Air 110’, for which Nauta curated the interior design. Lastly, we are working on the interior design of the third unit of Moonlight 44 currently under construction by Conrad Shipyard.

In addition, our partnership with Southern Wind is continuing: they just launched the Southern Wind 96 Liberty soon to be followed by a second SW 108, and under construction is a new model, the SW 100X. For all of these Nauta created both the interior and exterior design. There are also a number of series designs for Lagoon, Beneteau (Oceanis range), Pardo Yachts and Grand Soliel. At the moment, Nauta is working on 30 designs at the same time, with a team of around 25 people managed by myself and Massimo Gino. A great achievement which started a long time ago from a passion for the sea and for sailing that just gets stronger over time.”

Topics: Nauta Design